Analyze commercial brewing methods for high-volume cafes. Compare extraction yields, equipment TCO, and workflow efficiency for B2B applications.

This article is part of our Coffee Machine Knowledge series.

For a complete overview, visit our Coffee Maker Types guide.

In the competitive landscape of commercial coffee distribution and high-end hospitality, selecting the correct brewing methodology is not merely a matter of taste—it is an engineering decision that impacts workflow, profitability, and customer retention. As a Senior Coffee Machine Engineer, I analyze brewing methods not just by the cup profile, but by the hydraulic precision, thermal thermodynamics, and operational reliability required to execute them at scale.

This technical guide dissects common commercial coffee brewing methods through the lens of extraction science and equipment engineering, providing B2B professionals with the data needed to make informed infrastructure investments.

Espresso remains the cornerstone of the modern cafe menu, driven by rapid extraction under high pressure. Technically, this involves forcing water at 91-95°C through a compacted cake of coffee grounds at 9 bars (approx. 130 PSI) of pressure. However, in a commercial context, the stability of these variables defines the machine’s value.

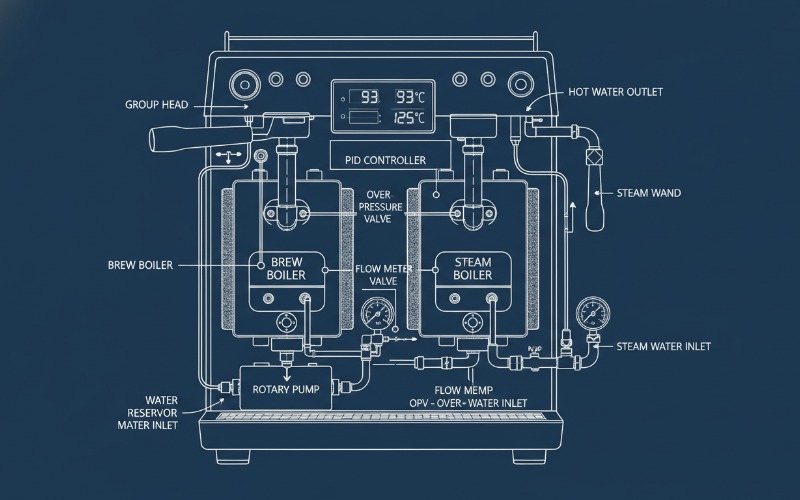

The standard 9-bar extraction is achieved via rotary vane pumps, which offer superior longevity and consistency compared to vibration pumps found in prosumer gear. Advanced commercial units now utilize gear pumps to facilitate pressure profiling—the ability to manipulate pressure during the shot.

For high-volume B2B applications, Multi-Boiler systems with Saturated Group Heads are the gold standard. Unlike Heat Exchanger (HX) systems, which rely on a cooling flush and indirect heating, multi-boiler systems use dedicated boilers for steam and brewing.

PID (Proportional-Integral-Derivative) controllers monitor and adjust the heating element thousands of times per second. In a saturated group design, the boiler water circulates directly through the group head, ensuring the thermal mass remains identical to the brew water temperature. This guarantees that the 100th shot of the day is extracted at the exact same temperature as the first, a critical metric for franchise consistency.

While espresso relies on pressure, filtration methods rely on gravity and strict adherence to the SCA (Specialty Coffee Association) Gold Cup standards. The objective is an Extraction Yield of 18-22% and a TDS of 1.15-1.35%.

Modern batch brewers are sophisticated thermal management systems. They must maintain a slurry temperature between 92°C and 96°C throughout a 2-4 liter brew cycle.

Engineering Challenges:

Manual pour-over (V60, Kalita Wave) offers theatrical value and single-cup customization but poses significant workflow bottlenecks. The variable of human error in pouring turbulence and rate can lead to inconsistent TDS.

Automated Solution: Systems like the Poursteady or Marco SP9 bridge this gap. They utilize robotics to replicate specific pouring patterns (spirals, pulses) with volumetric precision. This allows a single barista to manage 3-5 brewers simultaneously, drastically improving ROI per labor hour while maintaining the “craft” aesthetic.

Immersion brewing (French Press, Aeropress, Cold Brew) involves suspending coffee grounds in water for the entire extraction duration. This results in a higher body due to the retention of oils and fines (suspended solids) that paper filters typically remove.

Cold brew has shifted from a trend to a staple B2B requirement. The extraction dynamics differ fundamentally because oxidation and acid degradation occur much slower at low temperatures.

| Brewing Method | Target TDS % | Equipment Cost (Est.) | Labor Intensity | Maintenance Needs | Best Commercial Application |

|---|---|---|---|---|---|

| Espresso (Multi-Boiler) | 8.0% – 12.0% | High ($15k – $30k) | High (Requires Training) | Daily Backflush / Annual Service | High-volume cafes, restaurants |

| Batch Brew (SCA Cert.) | 1.15% – 1.35% | Medium ($1k – $3k) | Low (One-touch) | Descaling / Spray head cleaning | Breakfast service, offices, diners |

| Manual Pour-Over | 1.20% – 1.45% | Low ($50 per setup) | Very High (1:1 Staffing) | Minimal | Specialty brew bars, tasting rooms |

| Automated Pour-Over | 1.20% – 1.45% | High ($5k – $15k) | Medium (Multitasking) | Hydraulic system cleaning | High-traffic specialty cafes |

| Nitro/Cold Brew | 1.50% – 2.50% | Medium (Kegs/Taps) | Low (Prep in advance) | Line sanitation (Critical) | Summer menus, grab-and-go |

When advising commercial clients, the initial purchase price is only one component. The TCO includes energy consumption, maintenance, and water filtration requirements.

Modern espresso machines with independent boilers allow operators to switch off unused groups during off-peak hours. Insulated boilers reduce thermal loss by up to 40%. For a machine running 24/7, this equates to significant OpEx savings annually.

Scale accumulation is the primary cause of hydraulic failure. All commercial brewing methods require water treated to specific hardness levels (typically 40-80 ppm alkalinity). Reverse Osmosis (RO) systems with remineralization cartridges are recommended to protect the investment while ensuring the magnesium and calcium necessary for flavor extraction are present.

According to SCA standards, the ideal extraction yield is between 18% and 22%. Under 18% results in sour, underextracted flavors, while over 22% draws out bitter, hydrophobic compounds. Consistent commercial equipment is designed specifically to keep brewing within this narrow window repeatedly.

PID controllers replace traditional mechanical pressure stats. They actively monitor boiler temperature and pulse the heating element to maintain stability within 0.1°C to 0.5°C. This prevents the “temperature surfing” required on older machines and ensures that thermal shock does not ruin the espresso’s flavor profile.

Yes. While manual start/stop requires high skill, volumetric dosing measures the exact water volume flowing through the flowmeter. This allows the barista to focus on customer service and milk texturing while the machine ensures the brew ratio remains precise, significantly increasing workflow speed and consistency.

Bypass allows the machine to brew a concentrate at an optimal extraction rate and then dilute it to the desired drinking strength (TDS). This prevents the over-extraction that would occur if all the water were forced through the coffee bed, which would extend contact time excessively and result in bitterness.

Understanding how coffee machines work helps you select the right equipment for your business.

Explore our commercial coffee machine range designed for cafés, offices, and hospitality environments.

Back to How Coffee Machine Works for more related knowledge.