This article is part of our Coffee Machine Knowledge series.

For a complete overview, visit our How Coffee Machine Works guide.

In the realm of commercial coffee preparation, coffee extraction time is not merely a stopwatch exercise; it is the definitive variable indicating the success of hydraulic resistance against pump pressure. For B2B distributors and equipment technicians, understanding the physics behind extraction time is crucial for calibrating machines like the La Marzocco KB90 or Victoria Arduino Eagle One. This guide moves beyond the basic “golden rule” to explore the hydrodynamics, thermal stability, and chemical solubility that define the perfect espresso shot.

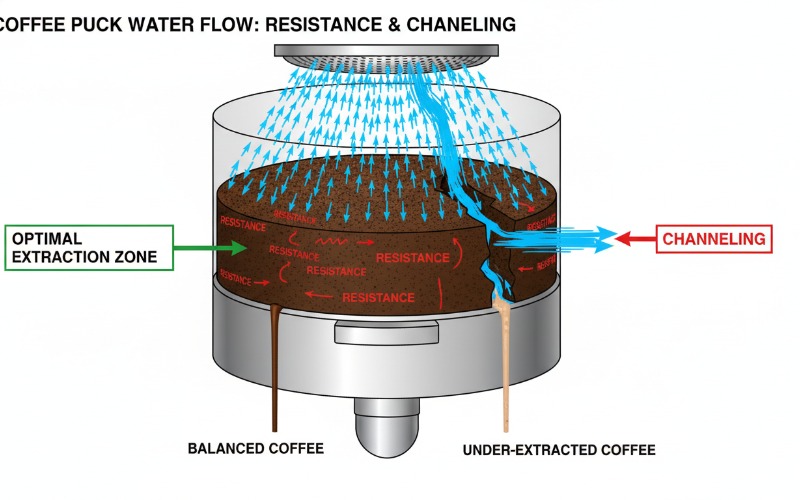

Extraction is a chemical process where water acts as a solvent to dissolve soluble compounds from the coffee bed. The duration of this contact time determines the flavor profile and chemical composition of the final beverage. However, time is a dependent variable, resulting from the interaction between pump pressure, grind surface area, and puck resistance.

To understand why specific timeframes are recommended, we must analyze the order in which compounds dissolve. This is governed by molecular weight and solubility:

If the coffee extraction time is too short (under-extraction), the profile is dominated by acids, lacking sweetness. If too long (over-extraction), the solvent begins creating hydrolysis in the plant cellulose, resulting in a dry, bitter finish.

For technicians setting up commercial equipment, the goal is to achieve the target extraction yield (18%–22%) within a time window that suits the workflow. This requires a deep understanding of the machine’s hydraulic system.

Standard rotary pumps are set to 9 bar (approximately 130 PSI). However, the flow rate is restricted by the gicleur (restrictor), typically ranging from 0.6mm to 0.8mm. A smaller gicleur slows the water debit, allowing for a gentler saturation but potentially extending the extraction time. When diagnosing inconsistent times across different group heads on a multi-boiler machine, scale buildup in the gicleur is a primary suspect, altering the flow rate and invalidating the programmed volumetric dosing.

Thermal stability is critical. A PID (Proportional-Integral-Derivative) controller ensures the water temperature remains constant. Water that is too cool extracts slower; water that is too hot extracts faster due to increased kinetic energy. In high-volume environments, a machine with poor thermal recovery will result in drifting extraction times during rush hours, leading to inconsistent product quality.

Modern commercial machines, such as the Sanremo Opera or Slayer Steam, utilize advanced pre-infusion or needle-valve technology. This fundamentally changes the metrics for coffee extraction time.

Pre-infusion saturates the puck at low pressure (line pressure or restricted flow) before the pump ramps to full 9 bar. This allows the coffee bed to swell, reducing the risk of channeling.

For B2B distributors, it is vital to educate clients that a 35-second shot on a Slayer is not “slow”—it is a design feature that allows for much finer grinding and higher extraction yields without bitterness.

The following table outlines the technical specifications for different extraction styles common in modern specialty coffee.

| Profile Type | Pressure Max | Avg Flow Rate | Target Time | Grind Character | Sensory Outcome |

|---|---|---|---|---|---|

| Traditional Italian | 9 Bar | 2.0 – 2.5 ml/s | 25 – 30 sec | Medium-Fine | High Body, Low Acidity |

| Modern Specialty | 9 Bar | 1.8 – 2.2 ml/s | 28 – 32 sec | Fine | Balanced, High Sweetness |

| Turbo Shot | 6 Bar | 2.8 – 3.5 ml/s | 15 – 20 sec | Coarser | High Acidity, High Clarity |

| Flow Profiling | Variable | Variable | 35 – 50 sec | Very Fine | High Texture, Complex |

Subjective tasting is insufficient for B2B quality control. We rely on refractometry to measure Total Dissolved Solids (TDS). The relationship between time and TDS is the cornerstone of extraction science.

Extraction Yield % = (Beverage Weight [g] × TDS %) / Dose Weight [g]

If an extraction time is extended by grinding finer (increasing surface area), the Extraction Yield generally increases, up to the point of channeling. If time is extended merely by increasing the ratio (flowing more water), the Yield increases but the TDS (strength) decreases. Professionals aim for an Extraction Yield of 19-21% for modern espresso. Achieving this consistently requires a deviation in shot time of no more than +/- 2 seconds per cycle.

When machines are deployed in the field, technicians often face complaints of inconsistent timing. Here is a diagnostic protocol:

For cafe owners, extraction time is a metric of efficiency. A variance of 5 seconds per shot, over 500 shots a day, results in significant labor loss and potential customer wait times. Furthermore, inconsistent times lead to “sink shots”—beverages poured down the drain due to poor quality. High-end equipment with gravimetric technology (weighing output in real-time) or advanced volumetric dosing helps mitigate this risk, ensuring the Total Cost of Ownership remains low by minimizing waste.

Not necessarily. While traditional espresso targets 25-30 seconds, modern “Turbo Shots” utilize coarser grinds, lower pressure (6 bar), and faster times (15-20s) to achieve high extraction yields with distinct clarity. However, on standard 9-bar equipment, 20 seconds usually indicates under-extraction.

Pre-infusion adds time to the start of the shot without adding significant volume in the cup. If you program a 5-second pre-infusion, your total timer might read 32-34 seconds, but the active extraction phase remains similar to a standard shot. Always account for the low-pressure phase when setting recipe parameters.

This is typically a thermal stability issue. If the boiler cannot recover heat fast enough, the water temperature drops. Cooler water dissolves solids slower, potentially changing the flow dynamics. Alternatively, as grinders heat up, the burrs expand and the coffee oils become more fluid, often requiring a coarser adjustment to maintain the same time.

Train baristas to treat time as a consequence, not a target. They should dial in by taste and ratio first. Once the flavor is optimized, the resulting time (e.g., 28 seconds) becomes the benchmark for consistency for that specific coffee batch.