Technical comparison of hydraulic systems, thermal stability, and duty cycles in commercial vs home espresso machines for B2B procurement.

For B2B distributors and facility managers, the distinction between a high-end “prosumer” espresso machine and a true commercial-grade system is often blurred by marketing terminology. However, from an engineering perspective, the divergence in hydraulic performance, thermal thermodynamics, and component longevity is stark. Specifying the wrong equipment for a high-volume hospitality environment results not only in inconsistent extraction yields but also in catastrophic equipment failure and operational downtime.

This technical analysis dissects the internal architecture of commercial versus domestic espresso machinery, focusing on the critical systems that define extraction quality and Total Cost of Ownership (TCO).

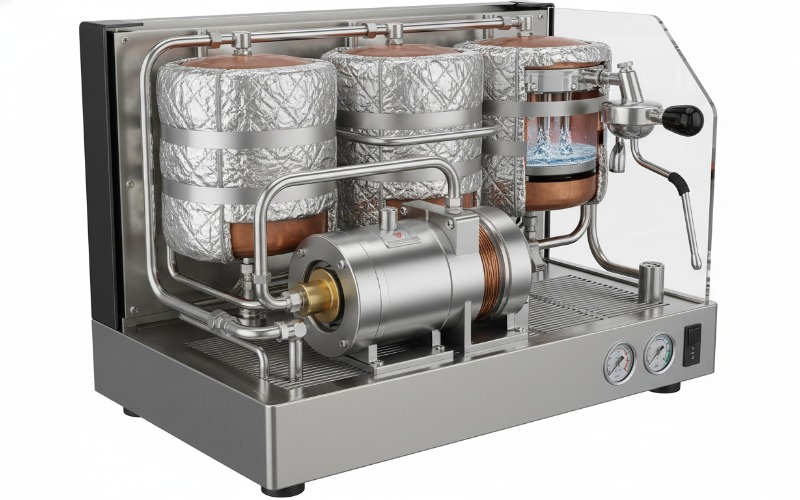

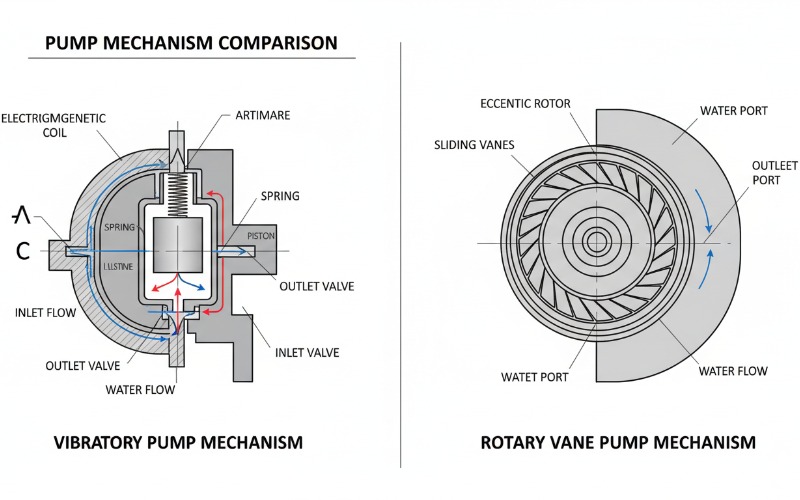

The heart of any espresso machine is its hydraulic system. The primary differentiator between commercial and home units lies in the pump technology and the water delivery network.

Commercial Standard (Rotary Vane): Commercial machines exclusively utilize balanced bypass rotary vane pumps. These large, motor-driven pumps generate pressure via a spinning rotor housed within a chamber. Crucially, they offer instant pressure ramp-up and, more importantly, flow-independent pressure stability. Whether the machine is dosing one group or three groups simultaneously, the rotary pump maintains a flat 9 bar pressure profile due to its high displacement capability.

Domestic Standard (Vibratory): Home machines typically employ solenoid-driven vibratory pumps. These operate on a piston principle oscillating at 60Hz. The critical engineering flaw in a commercial context is the inverse relationship between pressure and flow rate. As the flow rate increases (e.g., a coarser grind or channeling), the pressure delivered by a vibratory pump drops significantly. This lack of hydraulic consistency makes achieving reproducible Extraction Yield % nearly impossible in a high-volume setting.

Commercial units are hard-plumbed into the water mains. This allows for “line-pressure pre-infusion,” where mains pressure (typically 2-4 bar) saturates the coffee puck before the pump engages. This creates a uniform hydraulic resistance, mitigating channeling. Reservoir-fed home machines rely on pump pulsing to simulate pre-infusion, which is less effective at normalizing density gradients within the coffee bed.

Temperature stability is the single most critical variable in espresso extraction. A variance of just 1°C can alter the solubility of lipids and acids, changing the flavor profile from sweet to sour or bitter.

Multi-Boiler Systems: Modern commercial machines employ independent boilers for steam and brewing. The brew boilers are often saturated, meaning they are physically integrated with the group head. This massive thermal mass ensures that the water path from the boiler to the dispersion screen experiences zero thermal loss. With heating elements often exceeding 4000W-6000W, recovery time is instantaneous.

Single Boiler and Heat Exchangers (HX): Home machines often use a single boiler or an HX system. In an HX system, brew water is flash-heated by passing through a tube inside the steam boiler. While efficient for low volume, this system requires “cooling flushes” to stabilize temperature and struggles to maintain intra-shot stability during rapid-fire extraction sequences.

Proportional-Integral-Derivative (PID) controllers are standard in commercial equipment. Unlike simple thermostats with a wide deadband (hysteresis), PID controllers use predictive algorithms to pulse heating elements. In a commercial setting, the PID controller anticipates temperature drops based on flow meter activity, engaging the heating element aggressively to prevent thermal droop during the shot.

In a B2B environment, consistency translates to customer retention. Commercial machines utilize precision flowmeters to measure water volume for every shot.

While the initial capital expenditure (CapEx) for a commercial machine is significantly higher—often 5x to 10x that of a home machine—the operational analysis favors commercial hardware for business applications.

Commercial machines are built with copper, brass, and stainless steel chassis. Internal components, such as solenoid valves (3-way valves), are rated for millions of actuation cycles. A home machine’s solenoid is often smaller, prone to overheating, and rated for intermittent use. In a cafe making 200 coffees a day, a home machine’s pump and heating element would likely fail within 3-6 months, leading to service call-out fees and revenue loss.

For B2B distributors, recommending non-certified equipment is a liability risk. Commercial machines must carry certifications such as:

| Feature | Home / Prosumer Machine | Commercial Machine | Operational Impact |

|---|---|---|---|

| Pump Type | Vibratory (Piston) | Rotary Vane | Rotary ensures quiet, constant pressure at any flow rate. |

| Boiler Capacity | 0.5L – 2L (Total) | 7L – 14L+ (Steam) / 0.5L+ (Brew) | Large capacity allows simultaneous steaming and brewing without pressure loss. |

| Heating Power | 1200W – 1600W (110V/220V) | 3000W – 6000W+ (220V/380V) | Rapid recovery time; zero wait between shots. |

| Temperature Control | Thermostat or Basic PID | Multi-zone PID / Saturated Groups | Maintains intra-shot temp stability within 0.5°C. |

| Water Source | Reservoir (Tank) | Direct Plumb-in + Drain | Eliminates manual refilling; enables line-pressure pre-infusion. |

| Certifications | Consumer CE / UL | NSF / ANSI / Commercial UL | Mandatory for health inspections and business insurance. |

While machines like the Linea Mini are NSF-rated and engineered with commercial parts, they are volume-limited. For a low-volume boutique or a restaurant serving <50 coffees/day, they are sufficient. However, for a primary cafe setting, the smaller boiler size and physical workspace (drip tray size, steam wand ergonomics) will bottle-neck workflow during peak hours.

This is a function of boiler volume and heating element density. Home machines have small steam boilers (1-2 liters). As steam is released, pressure drops rapidly, and the heating element cannot replenish the thermal energy fast enough to maintain phase equilibrium. Commercial boilers (7-14 liters) hold a massive reserve of potential energy, providing infinite dry steam.

With proper preventative maintenance (filtration, gasket changes, descaling), a commercial chassis is designed to last 10-15 years. Components like pumps and solenoids are consumable but easily replaceable. In contrast, home machines are often designed with planned obsolescence or non-serviceable integrated components.